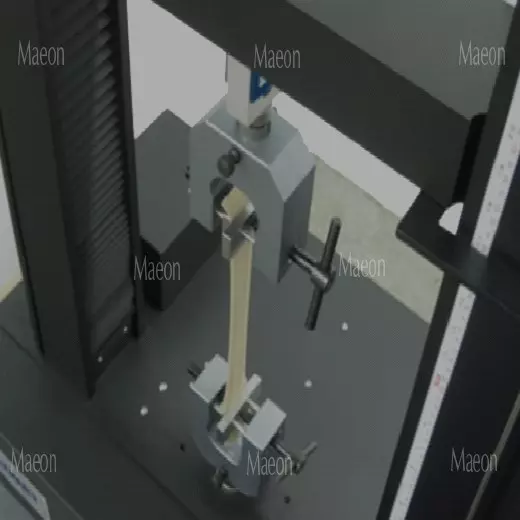

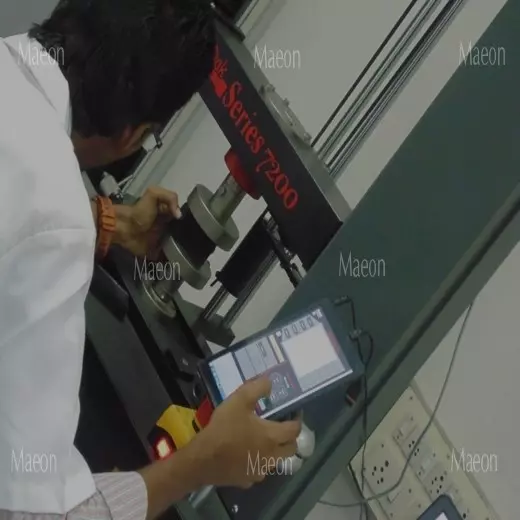

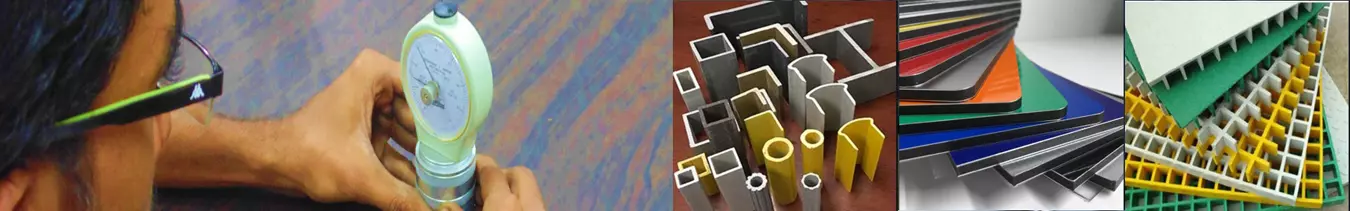

composite test labMaeon Laboratory is a specialized Composite testing laboratory in Chennai, facilitated with advanced equipment and expertise to conduct comprehensive testing and analysis of composite materials. Our laboratories play a critical role in ensuring the quality, performance, and safety of composite materials used in various industries.

composite test labMaeon Laboratory is a specialized Composite testing laboratory in Chennai, facilitated with advanced equipment and expertise to conduct comprehensive testing and analysis of composite materials. Our laboratories play a critical role in ensuring the quality, performance, and safety of composite materials used in various industries.

composite test lab Reinforced plastic composites and the Polymer Matrix composites, generally consists of a resin reinforced with fibres, such as fibre glass FRP GRP FGRP, graphite and aramind, carbon fibre wood particles and others, the matric being thermosets or thermoplastics.

composite test lab Reinforced plastic composites and the Polymer Matrix composites, generally consists of a resin reinforced with fibres, such as fibre glass FRP GRP FGRP, graphite and aramind, carbon fibre wood particles and others, the matric being thermosets or thermoplastics.

composite test lab Being a versatile material it finds application in many industries, replacing metal members, such as Automotive body parts, Industrial containers and pipings, reaction vessels, architectural applications including , Composite panels, Hard board panels, Decorative laminates, Fibre board, particle boards, PVC panels, Aluminium composites, thermal insulation applications, roads and bridges, railways, aerospace, wind mills etc..,

composite test lab Being a versatile material it finds application in many industries, replacing metal members, such as Automotive body parts, Industrial containers and pipings, reaction vessels, architectural applications including , Composite panels, Hard board panels, Decorative laminates, Fibre board, particle boards, PVC panels, Aluminium composites, thermal insulation applications, roads and bridges, railways, aerospace, wind mills etc..,

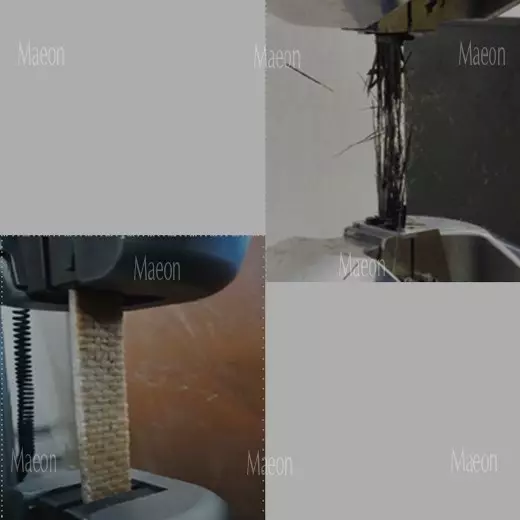

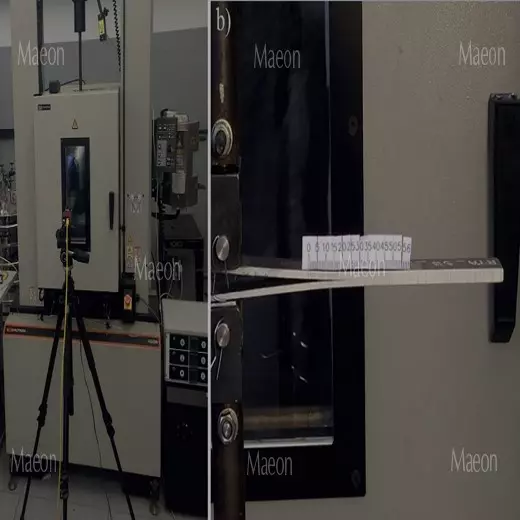

In composite materials testing, specific tests are conducted to assess the material's mechanical behavior, structural integrity, and response to different environmental conditions. These tests include tensile testing, flexural testing, compression testing, shear testing, impact testing, and fatigue testing. Additionally, non-destructive testing techniques such as ultrasonic testing, radiography, and thermography are used to detect internal flaws, defects, or delaminations in the composite structure.

In composite materials testing, specific tests are conducted to assess the material's mechanical behavior, structural integrity, and response to different environmental conditions. These tests include tensile testing, flexural testing, compression testing, shear testing, impact testing, and fatigue testing. Additionally, non-destructive testing techniques such as ultrasonic testing, radiography, and thermography are used to detect internal flaws, defects, or delaminations in the composite structure.

composite materials testingLaboratory also covers chemical composition analysis to understand the content of any unknown Composite material testing. Methods uses FTIR analysis, TGA analsis, DSC analysis and wet chemistry methods of analysis.

composite materials testingLaboratory also covers chemical composition analysis to understand the content of any unknown Composite material testing. Methods uses FTIR analysis, TGA analsis, DSC analysis and wet chemistry methods of analysis.

By conducting complete composite materials testing, manufacturers can ensure that the materials meet the required specifications and performance standards. It helps optimize the design and manufacturing processes, enhancing product quality and ensuring the safety and reliability of composite-based products in industries such as aerospace, automotive, construction, and many others.

By conducting complete composite materials testing, manufacturers can ensure that the materials meet the required specifications and performance standards. It helps optimize the design and manufacturing processes, enhancing product quality and ensuring the safety and reliability of composite-based products in industries such as aerospace, automotive, construction, and many others.

This test method covers the determination of the tensile properties of unreinforced and reinforced plastics in the form of standard dumbbell-shaped test specimens when tested under defined conditions of pretreatment, temperature, humidity, and testing machine speed.

This test method determines the in-plane tensile properties of polymer matrix composite materials reinforced by high-modulus fibers. The composite material forms are limited to continuous fiber or discontinuous fiber-reinforced composites in which the laminate is balanced and symmetric with respect to the test direction

| CP1ME-1 |

Tensile Properties of composites – general |

ASTM D638, ISO 527-4/5/2 |

| CP1ME-2 |

Tensile Properties of composites |

ASTM D3039, ISO 527-4/5 |

This test method determines the quasi-static longitudinal tensile strength and elongation properties of fiber reinforced polymer matrix (FRP) composite bars commonly used as tensile elements in reinforced, prestressed, or post-tensioned concrete.

This test method determines the open-hole tensile strength of multidirectional polymer matrix composite laminates reinforced by high-modulus fibers. The composite material forms are limited to continuous-fiber or discontinuous-fiber (tape or fabric, or both) reinforced composites in which the laminate is balanced and symmetric with respect to the test direction.

| CP1ME-3 |

Tensile Properties of FRP - Composite bars |

ASTM D7205 |

| CP1ME-4 |

Open hole Tensile strength |

ASTM D5766 |

Compressive Property Test

This test method determines the in-plane compressive properties of polymer matrix composite materials reinforced by high-modulus fibers. The composite material forms are limited to continuous-fiber or discontinuous-fiber reinforced composites for which the elastic properties are specially orthotropic with respect to the test direction

This test method covers the determination of the mechanical properties of unreinforced and reinforced rigid plastics, including high-modulus composites, when loaded in compression at relatively low uniform rates of straining or loading.

This test method covers the determination of the in-plane shear strength of reinforced thermosetting plastics in flat sheet form in thicknesses ranging from 2.54 to 6.60 mm (0.100 to 0.260 in.). This protocol in not for reinforced pultruded thermoset products

| CP1ME-5 |

Compressive properties by Shear loading |

ASTM D3410 |

| CP1ME-6 |

Compression Strength and Modulus of composites |

ASTM D695, ISO 14126, ISO 604M |

| CP1ME-7 |

Double notched shear test - In plane shear |

ASTM D3846, ISO 14129 |

This test method determines the in-plane shear properties of high-modulus fiber-reinforced composite materials by either of two procedures.

This test method covers the shear properties of composite materials reinforced by high-modulus fibers. The composite materials are limited to continuous-fiber or discontinuous-fiber-reinforced composites.

| CP1ME-8 |

In-Plane Shear Properties by Rail Shear |

ASTM D4255 |

| CP1ME-9 |

Shear Properties by V Notched Beam |

ASTM D5379 |

These test methods are used to determine the flexural properties of unreinforced and reinforced plastics, including high modulus composites and electrical insulating materials utilizing a three-point loading system to apply a load to a simply supported beam (specimen). The method is generally applicable to both rigid and semi-rigid materials, but flexural strength cannot be determined for those materials that do not break or yield in the outer surface of the test specimen

This test method covers the determination of flexural properties of unreinforced and reinforced plastics, including high-modulus composites and electrical insulating materials in the form of rectangular bars molded directly or cut from sheets, plates, or molded shapes. These test methods are generally applicable to rigid and semirigid materials

| CP1ME-11 |

Flexural strength and Modulus of Composites |

ASTM D790 ISO 14125 ISO 178 |

| CP1ME-12 |

Flexural strength of Composites by 4 point bending |

ASTM D6272, ISO 14125, ISO 178 |

Interlaminar Fracture Property Test

This test method determines the short-beam strength of high-modulus fiber-reinforced composite materials. The specimen is a short beam machined from a curved or a flat laminate up to 6.00 mm [0.25 in.] thick. The beam is loaded in three-point bending.

This test method determines the in-plane shear response of polymer matrix composite materials reinforced by high-modulus fibers. The composite material form is limited to a continuous-fiber-reinforced composite ±45° laminate capable of being tension tested in the laminate x direction.

| CP1ME-12 |

Short beam strength |

ASTM D2344 |

| CP1ME-13 |

±45° InPlane Shear Response |

ASTM 3518 ISO 14129 |

Interlaminar Fracture Property Test II

This test method describes the determination of the opening Mode I interlaminar fracture toughness, GIc, of continuous fiber-reinforced composite materials using the double cantilever beam (DCB) specimen

This test method covers the determination of the shear properties of high-modulus fiber-reinforced composite materials by clamping the ends of a V-notched specimen between two pairs of loading rails. When loaded in tension, the rails introduce shear forces into the specimen through the specimen faces

| CP1ME-14 |

Interlaminar Fracture Toughness |

ASTM D5528 |

| CP1ME-15 |

V-notched rail shear (difficult) |

ASTM D 7078 |

Adhesion strength Property Test

This test method describes a lap shear test for use in measuring the bonding characteristics of adhesives for joining fiber reinforced plastics to themselves and to metals. The method is applicable to random and fiber oriented FRP.

This test method is intended to complement Test Method D1002 and extend its application to single-lap shear adhesive joints of rigid plastic adherends. The test method is useful for generating comparative shear strength data for joints made from a number of plastics.

This test method covers the preparation and testing of thick-adherend lap-shear samples for the determination of the stress-strain behavior of adhesives.

| CP1ME-16 |

Lap shear strength of FRP |

ASTM D5868 |

| CP1ME-17 |

Adhesion strength of bonded plastics |

ASTM D3163 / ASTM D3164 |

| CP1ME-18 |

Adhesion of composite to thick metal |

ASTM D5656 |

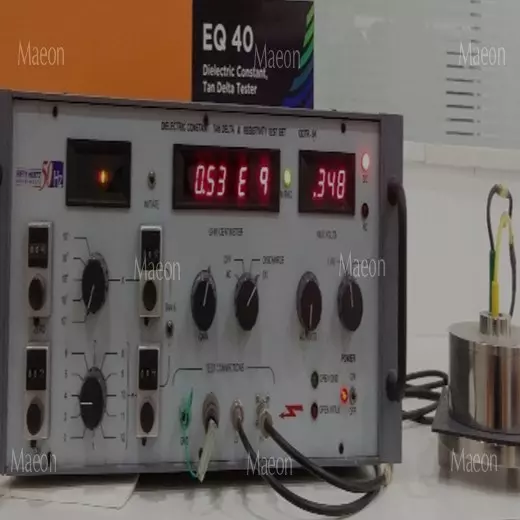

Many of the applications of Rubber materials involve measurement of electrical properties of Composites, some have been listed above.

| CP1EL-1 |

Volume Resistivity and Surface Resistivity of composites |

ASTM D257 |

| CP1EL-2 |

Dielectric Constant and Dissipation Factor of composites |

ASTM D150 |

| CP1EL-3 |

Dielectric Strength of composites |

ASTM D149 |

Composition Analysis Property Test

These test methods determine the constituent content of composite materials by one of two approaches. Test Method I physically removes the matrix by digestion or ignition Test Method II, applicable only to laminate materials of known fiber areal weight, calculates reinforcement.

This test method covers the determination of the ignition loss of cured reinforced resins. This ignition loss shall be considered to be the resin content within the limitations.

| CP1MT-1 |

Content Analysis of composites |

ASTM D3171 |

| CP1MT-2 |

Ignition loss of Composite materials |

ASTM D2584 |

Composition Analysis Property Test II

This test method covers determination of the coefficients of starting and sliding friction of plastic film and sheeting when sliding over itself or other substances at specified test conditions.

These test methods determine the constituent content of composite materials by one of two approaches. Test Method I physically removes the matrix by digestion or ignition Test Method II, applicable only to laminate materials of known fiber areal weight, calculates reinforcement.

| CP1MT-3 |

Water Absorption of composites |

ASTM C272 |

| CP1MT-4 |

Fiber volume fraction |

ASTMD 3171 |

The polymers in a given material or product can be determined by Infrared spectrophotometry. The infrared spectrum of the test specimen is superimposed on a reference spectrum and compared for determination of polymer used

We offer testing of plastics for the determination of Transition temperatures, such as Enthalpies of Fusion and Crystallization of Polymers – including Tm, Tg, Tc. Other measurements from DSC include Thermal stability, Decomposition temperature, Oxidative Induction Times etc.,

The composition of compound of rubber / plastics such as Low boiling fractions, polymer, carbon and fillers are quantitatively determined by TGA – Thermogravimetry. A small mass of test sample is subjected to controlled heating under specific environment and the mass loss over a temperature range is measured.

| CP1MT-5 |

Fourier Transform Infrared Spectroscopic analysis |

ASTM E168 |

| CP1MT-6 |

Thermo gravimetric analysis |

ASTM E1131 |

| CP1MT-7 |

Differential Scanning Calorimetric Analysis |

ASTM D3418 |

FRP, GRP, Particle boards, laminates

Maeon Laboratory provides best Testing services for Ply wood testing, MDF testing, HDF testing, Particle board testing, Door testing and also for Decorative laminate sheet testing, Aluminium Composite panels and PVC door panels. Refer to product standards and test standards listed below.

| CP1CV-1 |

High pressure decorative lamintaes |

IS 2046 |

| CP1CV-2 |

Particle board of wood and lignocellulosic |

IS 2380 |

| CP1CV-3 |

Particle board of wood and lignocellulosic |

IS 3087 |

| CP1CV-4 |

Fibre board medium density |

IS 12406 |

| CP1CV-5 |

Aluminum Composite Panel ACP PVDF |

|

| CP1CV-6 |

PVC Door panels |

|

| |

Thermosetting synthetic resin bonded laminated sheets |

IS 1998 |

| |

Phenolic Laminated Sheets |

IS 2036 |

composite testing laboratory

As a result of our best composite material testing laboratory in Chennai,composite testing laboratory we ensure our clients receive clear and accurate reporting from our testing personnel. Our experts provide various property testing and analysis results of composite material with standards and international standards. Our expert foam testing laboratory in chennai are well equipped to handle your Foam and sponge testing needs.

composite test labMaeon Laboratory is a specialized Composite testing laboratory in Chennai, facilitated with advanced equipment and expertise to conduct comprehensive testing and analysis of composite materials. Our laboratories play a critical role in ensuring the quality, performance, and safety of composite materials used in various industries.

composite test labMaeon Laboratory is a specialized Composite testing laboratory in Chennai, facilitated with advanced equipment and expertise to conduct comprehensive testing and analysis of composite materials. Our laboratories play a critical role in ensuring the quality, performance, and safety of composite materials used in various industries. composite test lab Reinforced plastic composites and the Polymer Matrix composites, generally consists of a resin reinforced with fibres, such as fibre glass FRP GRP FGRP, graphite and aramind, carbon fibre wood particles and others, the matric being thermosets or thermoplastics.

composite test lab Reinforced plastic composites and the Polymer Matrix composites, generally consists of a resin reinforced with fibres, such as fibre glass FRP GRP FGRP, graphite and aramind, carbon fibre wood particles and others, the matric being thermosets or thermoplastics. composite test lab Being a versatile material it finds application in many industries, replacing metal members, such as Automotive body parts, Industrial containers and pipings, reaction vessels, architectural applications including , Composite panels, Hard board panels, Decorative laminates, Fibre board, particle boards, PVC panels, Aluminium composites, thermal insulation applications, roads and bridges, railways, aerospace, wind mills etc..,

composite test lab Being a versatile material it finds application in many industries, replacing metal members, such as Automotive body parts, Industrial containers and pipings, reaction vessels, architectural applications including , Composite panels, Hard board panels, Decorative laminates, Fibre board, particle boards, PVC panels, Aluminium composites, thermal insulation applications, roads and bridges, railways, aerospace, wind mills etc.., In composite materials testing, specific tests are conducted to assess the material's mechanical behavior, structural integrity, and response to different environmental conditions. These tests include tensile testing, flexural testing, compression testing, shear testing, impact testing, and fatigue testing. Additionally, non-destructive testing techniques such as ultrasonic testing, radiography, and thermography are used to detect internal flaws, defects, or delaminations in the composite structure.

In composite materials testing, specific tests are conducted to assess the material's mechanical behavior, structural integrity, and response to different environmental conditions. These tests include tensile testing, flexural testing, compression testing, shear testing, impact testing, and fatigue testing. Additionally, non-destructive testing techniques such as ultrasonic testing, radiography, and thermography are used to detect internal flaws, defects, or delaminations in the composite structure. composite materials testingLaboratory also covers chemical composition analysis to understand the content of any unknown Composite material testing. Methods uses FTIR analysis, TGA analsis, DSC analysis and wet chemistry methods of analysis.

composite materials testingLaboratory also covers chemical composition analysis to understand the content of any unknown Composite material testing. Methods uses FTIR analysis, TGA analsis, DSC analysis and wet chemistry methods of analysis.  By conducting complete composite materials testing, manufacturers can ensure that the materials meet the required specifications and performance standards. It helps optimize the design and manufacturing processes, enhancing product quality and ensuring the safety and reliability of composite-based products in industries such as aerospace, automotive, construction, and many others.

By conducting complete composite materials testing, manufacturers can ensure that the materials meet the required specifications and performance standards. It helps optimize the design and manufacturing processes, enhancing product quality and ensuring the safety and reliability of composite-based products in industries such as aerospace, automotive, construction, and many others.