Foam testing laboratory is essential for ensuring that long-term storage inventories of foam concentrate are in good working order when they are needed to put out a fire. Maeon Laboratories is a reputable test house for foam testing, sponge testing, automotive foam testing, and insulation foam testing, as well as a variety of other tests conducted according to customer specifications or established international standards.

Foam testing laboratory is essential for ensuring that long-term storage inventories of foam concentrate are in good working order when they are needed to put out a fire. Maeon Laboratories is a reputable test house for foam testing, sponge testing, automotive foam testing, and insulation foam testing, as well as a variety of other tests conducted according to customer specifications or established international standards.

Maeon Laboratories is foam testing lab a dependable test house for Foam testing, Sponge testing,foam testing lab Automotive foam testing, insulation foam testing, for evaluating its properties through a number of tests conducted as per customer standards or published international standards.

Maeon Laboratories is foam testing lab a dependable test house for Foam testing, Sponge testing,foam testing lab Automotive foam testing, insulation foam testing, for evaluating its properties through a number of tests conducted as per customer standards or published international standards.

Cellular materials, Foam & Sponges, are wonder material possessing extraordinary range properties. Combined with special characteristics of each polymers it is made of, it finds numerous applications from comfort to high technology. Vowing to the unique combination of its properties like light weight, thermal insulation, resilience , sound absorption,foam testing lab air and fluid permeation etc. the material finds application in a wide spectrum of industries.

Cellular materials, Foam & Sponges, are wonder material possessing extraordinary range properties. Combined with special characteristics of each polymers it is made of, it finds numerous applications from comfort to high technology. Vowing to the unique combination of its properties like light weight, thermal insulation, resilience , sound absorption,foam testing lab air and fluid permeation etc. the material finds application in a wide spectrum of industries.

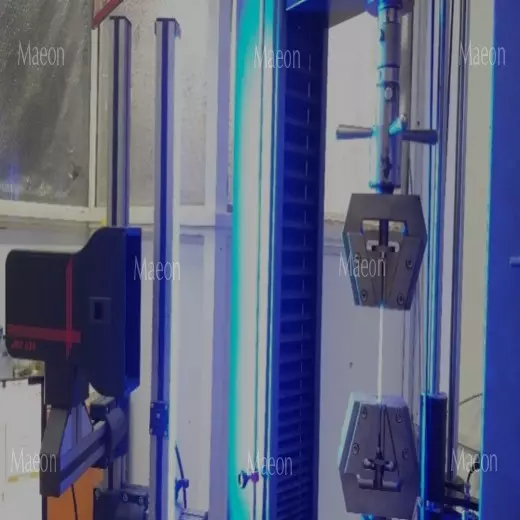

A fatigue test lab is a specialized facility designed to evaluate the durability and performance of materials, components, and structures under repetitive loading conditions. The primary objective of a fatigue test lab is to simulate and assess the effects of cyclic loading on the mechanical integrity and fatigue life of various materials and products.

A fatigue test lab is a specialized facility designed to evaluate the durability and performance of materials, components, and structures under repetitive loading conditions. The primary objective of a fatigue test lab is to simulate and assess the effects of cyclic loading on the mechanical integrity and fatigue life of various materials and products.

FO1ME-1 |

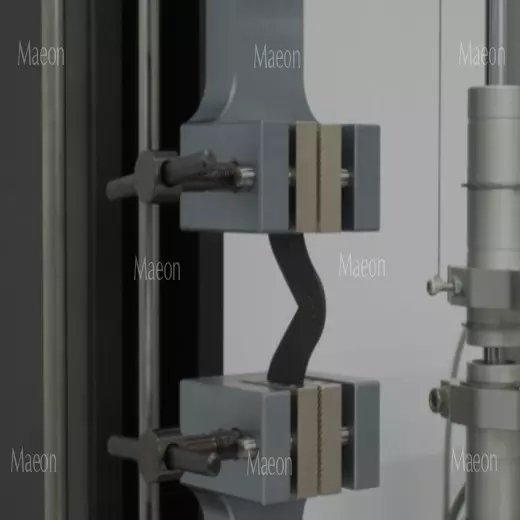

Tensile properties |

ASTM D1623, ISO 1926, ASTM D412, , ASTM D3574 CL E, ISO 1798, IS 7888 CL 5 |

|---|

FO1ME-16 |

Tear Strength |

ISO 8067, ISO 34-1, ASTM D3574, ASTM D3574 CL F |

|---|

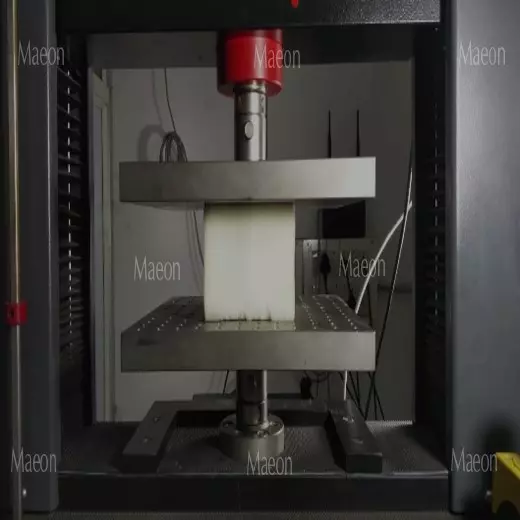

| FO1ME-2 | Compressive Properties of Rigid Cellular Plastics - Compression deflection, Compression Force Deflection CFD , Compression Set | ASTM D1621, ISO 844, ISO 3386-1, ISO 3386-2, ISO 11752, ASTM D1056 CL 17, ASTM D1056 CL 35, ASTM D1667 CL 16, ASTM D3574 CL C, ASTM D3575 CL D, IS 7888 CL 4, IS 11239-11, ASTM D1056 |

|---|---|---|

| FO1ME-3 | Indentation Force Deflection | ASTM D5672, ISO 2439, ASTM D3574 CL B1, ASTM D3574 CL B2, IS 7888 CL 6, IS 16774 |

| FO1ME-6 | Force Loss Test at Constant Deflection | ASTM D3574 CL I1 |

| FO1ME-24 | Hardness | MS 260-13 CL4.2, D3489-17 |

FO1ME-15 |

Compressive creep |

ISO 7616, ISO 7850, ISO 20392, ISO 10066, ASTM D3575 CL BB |

|---|---|---|

| FO1ME-9 | Recovery | ASTM D3574 CL M ASTM D6576 CL 14 |

| FO1ME-10 | Hysteresis Loss | ASTM D3574 CL X6 MS 257-06 CL 4.7 |

| FO1ME-11 | Compression Set | ISO 13362, ISO 1856, ASTM D1056 CL 50, ASTM D1667 CL 21, ASTM D3574 CL D, ASTM D3575 CL B, IS 7888 CL 8, MS 260-13 CL4.5, ASTM D1056 |

FO1ME-13 |

Flexural Strength |

ISO 1209-1, ISO 1209-2, IS 11239-10 |

|---|---|---|

| FO1ME-4 | Flexural Modulus | ISO 1209-3 |

| FO1MT-4 | Flexural Recovery | ASTM D3768 |

FO1ME-17 |

Ball Rebound resiliance |

ISO 8307, ASTM D3574 CL H, ASTM D3489, ASTM D2632 |

|---|

FO1ME-19 |

Peel strength |

MS 373-22, MS 320-11 |

|---|---|---|

| FO1ME-23 | Substrate adhesion | ISO 8873-1, |

FO1ME-18, 20, 27 |

Abrasion resistance |

ASTM D3389, ASTMD 3489-17, MS 300-22 |

|---|

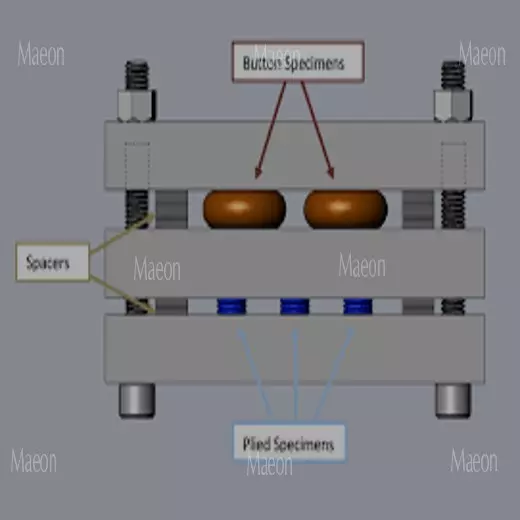

| FO1ME-4 | Fatigue by constant Strain | ISO 24999, ASTM D3574 CL |

|---|---|---|

| FO1ME-5 | Constant Load Pounding | ISO 3385, ASTM D3574 CL I3, IS 17115 |

| FO1ME-21 | Dynamic Cushioning | ASTM D1596 ISO 4651 |

FO1ME-25,7 |

Dynamic Fatigue by Roller Shear Constant Force |

ASTM D3574 CL I2, ISO 3385, IS 7888 CL 7 |

|---|---|---|

| FO1ME-26,8 | Dynamic Fatigue Carpet Cushion | D3574 CL 14 |

| FO1ME-12 | Shear properties – for rigid foam | ISO 1922 |

FO1TH-1 |

Thermal and Humid Aging |

ASTM D2126 , ASTM D3574 CL L, IS 7888 CL9 |

|---|---|---|

| FO1TH-9, 3 | Coeffıcient of Linear Thermal Expansion | ASTM D696, ISO 4897 |

| FO1TH-4 | Thermal Resistance | ISO 8301, ISO 8302, ISO 11561, ASTM D3574 CL K, ASTM D3489-17 |

| FO1TH-2 | Dimensional stability – Foam gaskets and seals | ISO 2796, ISO 7850, ASTM D2126, IS 11239-3, ASTM C509 Cl 11.4 |

| FO1TH-5 | Accelerated Ageing | ISO 2440, ASTM 1056 MS 260-13 CL4.3 |

| FO1TH-8 | Thermal stability | ASTM D3575 CL S |

| FO1TH-7 | Heat Ageing Volume Change | ASTM D1667 CL X1 |

| FO1TH-6 | Low Temperature Flexing (does not apply to latex foam rubber or ebonite cellular rubber) | ISO 6453, ASTM D1056 CL 57, ASTM C509 Cl 11.6ves |

| FO1TH-10 | Heat ageing | IS 7888 CL 10 |

| FO1TH-12 | Thermal Conductivity | ASTM C177-85 |

| FO1TH-13 | Low temperature properties | ASTM D746 |

FO1EN-1 |

Water vapour transmission |

IS 11239-4 ISO 1663, ASTM E96 |

|---|---|---|

| FO1EN-2 | Fluid Immersion Weight Change, Volume change | ASTM D1056 cl 27, ASTM D6576 CL 18 |

| FO1EN-3 | Steam autoclave ageing | ASTM D3574 CL J |

| FO1EN-4 | Water ageing | MS 373-22 , MS 700-60 |

| FO1MT-2 | Water Absorption of Rigid Cellular Plastics | ASTM D2842, ISO 2896, ISO 20393, ASTM D1056 CL 43, ASTM D1667 CL 26, ASTM D3575 CL L, MS 260-13 CL4.4, IS 11239-9, ASTM C509 Cl 11.7 |

FO1ME-22 |

Shrinkage |

ASTM D6576 CL 16 |

|---|---|---|

| FO1FL-1 | Flammability, LOI | ASTM D2863, ASTM D6576 CL 15, ISO 3582, ISO 9772, IS 7888 CL 11, IS 13360 P6 S24, IS 11239-12, ASTM C509 Cl 11.8, ISO 3582, ISO 9772 |

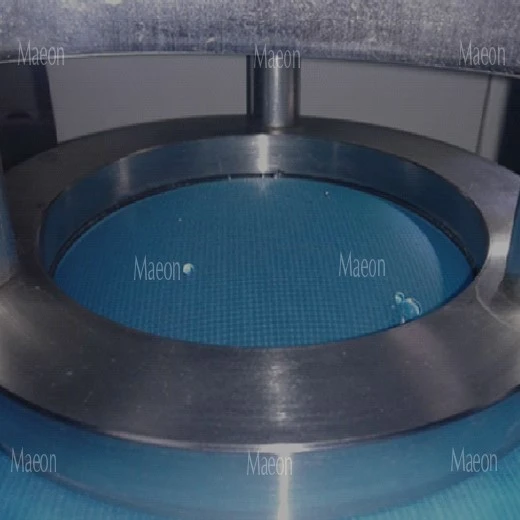

| FO1MT-7 | Air Flow Permeability, Air flow value | ISO 4638, ASTM D3574 CL G ISO 7231 |

| FO1MT-8 | ASH | ASTM D2584 |

| FO1MT-9 | STAINING | MS 260-13 CL4.8, MS 220-05 Cl 4.12, MS 269-03 Cl 4.12 |

| FO1MT-10 | Density | ASTM D3575-14 |

| FO1MT-6 | Linear Dimensions | ISO 1923, IS 7888 CL 3 |

| FO1MT-1 | Apparent Density of Rigid Cellular Plastics | ASTM D1622, ASTM D7710, ISO 845, ASTM D1056 CL 62, ASTM D1667 CL X3, ASTM D3574 CL A, ASTM D3575 CL W, IS 11239 P2 |

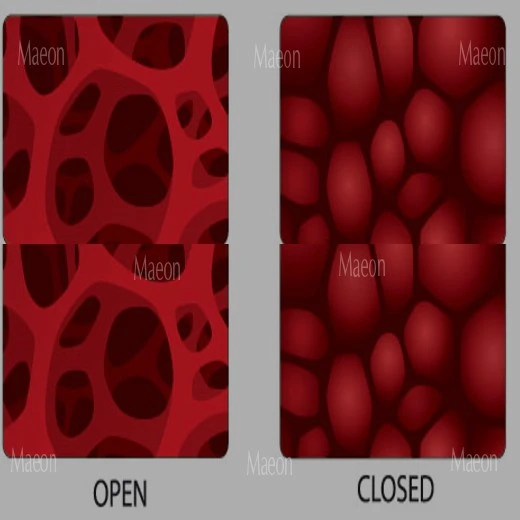

| FO1MT-5 | Open Cell Content of Rigid Cellular Plastics | ASTM D6226, ISO 4590, IS 11239-5 |

|---|---|---|

| FO1MT-3 | Cell Size of Rigid Cellular Plastics | ASTM D3576 |

| FO1FP-1 | Sponge or Expanded Rubber - Flexible | ASTM D1056 - 14 |

|---|---|---|

| FO1FP-2 | Poly (Vinyl Chloride) Foam (Closed-Cell) - Flexible | ASTM D1667 - 17 |

| FO1FP-3 | Microcellular Urethane Materials | ASTM D3489 - 17 |

| FO1FP-4 | Slab, Bonded, and Molded Urethane Foams – Flexible | ASTM D3574 – 17 |

| FO1FP-5 | Olefin Polymers – Flexible foam | ASTM D3575 - 14, ISO 7214:2012 |

| FO1FP-6 | Flexible Cellular Rubber Chemically Blown | ASTM D6576 - 13 |

| FO1FP-7 | Flexible Sponge and expanded foam – Specification | ISO 6916-2 |

| FO1FP-8 | Latex Foam Good | IS 1741 |

| FO1FP-9 | Flexible Polyurethane Foam for Domestic Mattresses | IS 7933 |

| FO1FP-10 | Flexible Polyurethane Foam for Domestic Mattresses | IS 7933 |

| FO1FP-11 | Cotton Pad/ Slab PU Foam | IS 7888-1976, MS 257-06, , MS 700-60 |

| FO1FP-12 | Crosslinked Polyethylene foam | IS 7098 |

Find the characteristics of foam and sponge material with numerous applications from comfort to high technology. We are experts in Foam Testing Laboratory in Chennai, above mentioned conducting results for various applications with quality and reliable analytic results to our valuable clients. Our film testing laboratories in Chennai, conducting film material property testing need with the best result.