Tube testing laboratory

MAEON Laboratories are pioneers in conducting Hose testing, Tube testing, Pipe testing for various industrial, agricultural, water and fuel transfer, domestic product applications The range of tests required for hose and pipe testing include those carried out directly on the product and tests made on the materials used for the Hose/Pipe products.

MAEON Laboratories are pioneers in conducting Hose testing, Tube testing, Pipe testing for various industrial, agricultural, water and fuel transfer, domestic product applications The range of tests required for hose and pipe testing include those carried out directly on the product and tests made on the materials used for the Hose/Pipe products.

We specialize in product testing laboratory, where products are evaluated and ensured to meet your quality, safety, and regulatory standards. Our laboratories have advanced equipment and experts who conduct tests to analyze performance, durability, chemical composition, and reliability. The results of these tests help your business to improve products, enhance customer satisfaction, and comply with industry regulations. Product testing laboratories play a vital role in ensuring high-quality products and protecting consumers.

We specialize in product testing laboratory, where products are evaluated and ensured to meet your quality, safety, and regulatory standards. Our laboratories have advanced equipment and experts who conduct tests to analyze performance, durability, chemical composition, and reliability. The results of these tests help your business to improve products, enhance customer satisfaction, and comply with industry regulations. Product testing laboratories play a vital role in ensuring high-quality products and protecting consumers.

Tube testing laboratory is gradually being phased out of normal hospital pretransfusion testing in favor of gel and solid-phase testing, as it is deemed less sensitive than more current methods.

Tube testing laboratory is gradually being phased out of normal hospital pretransfusion testing in favor of gel and solid-phase testing, as it is deemed less sensitive than more current methods.

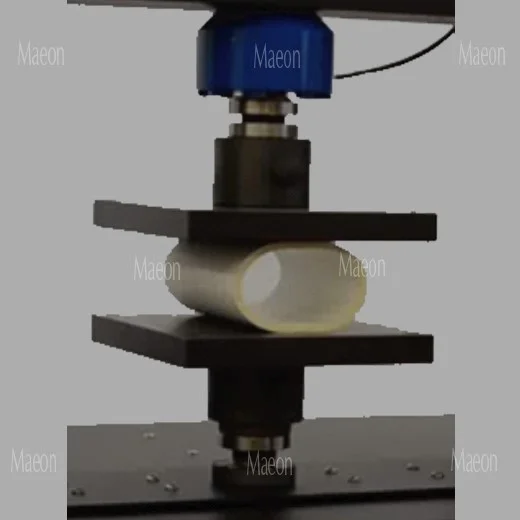

Plastic pipe testing is required throughout the manufacturing process of various pipes as as PVC, HDPE, and others. During the production process, this testing is necessary to determine the objects' strength, quality, and resistance.There are a variety of tests that must be performed on PVC pipe testing, and we offer a variety of equipments that can produce accurate findings.

Plastic pipe testing is required throughout the manufacturing process of various pipes as as PVC, HDPE, and others. During the production process, this testing is necessary to determine the objects' strength, quality, and resistance.There are a variety of tests that must be performed on PVC pipe testing, and we offer a variety of equipments that can produce accurate findings.

HDPE pipe testing is a flexible plastic pipe that is used to transport fluids and gases. It is frequently utilised to replace ageing concrete or steel mains pipes. Its high level of impermeability and strong molecular bond make it suited for high pressure pipelines, and it is made from the thermoplastic HDPE.

HDPE pipe testing is a flexible plastic pipe that is used to transport fluids and gases. It is frequently utilised to replace ageing concrete or steel mains pipes. Its high level of impermeability and strong molecular bond make it suited for high pressure pipelines, and it is made from the thermoplastic HDPE.

Hose and Tubes - Testing

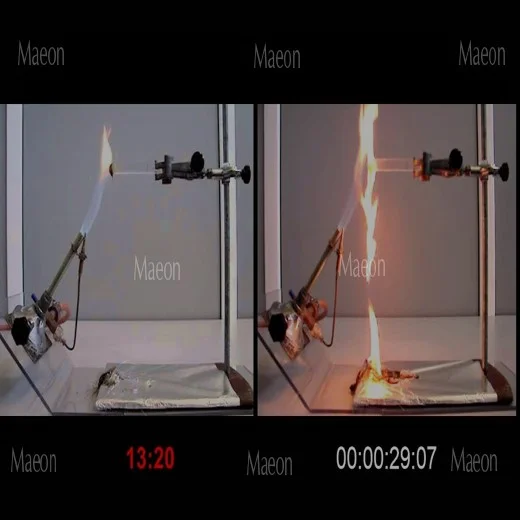

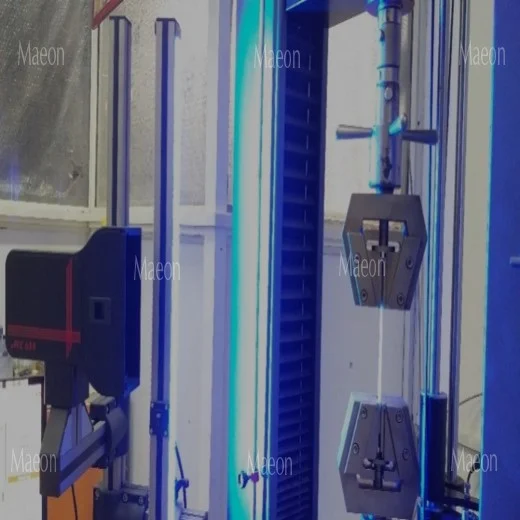

The different tests conducted for Hoses and Tubings are their Internal and external Dimensions, Mechanical Properties, Pressure testing, static and dynamic and vacuum, Fuel, air, water permeability, Envirnoment tests, Thermal ageing properties, Hot and cold, Flame resistance, electrical properties and Odour tests etc.

Some of National, International standards to which the hose testing and tube testing are conducted at MAEON Labortatories listed above.

|

Hose and Tubes - Testing |

ASTM D380, ISO 1402, ISO 6605, ISO 4642, ISO 10619, ISO 1825, ISO 1825, SAE J343, SAE J2260,SAE AS1472, SAE AS4468F, SAE J343, SAE AS1472A, IS 7651, IS 7593, IS 15913 |

| |

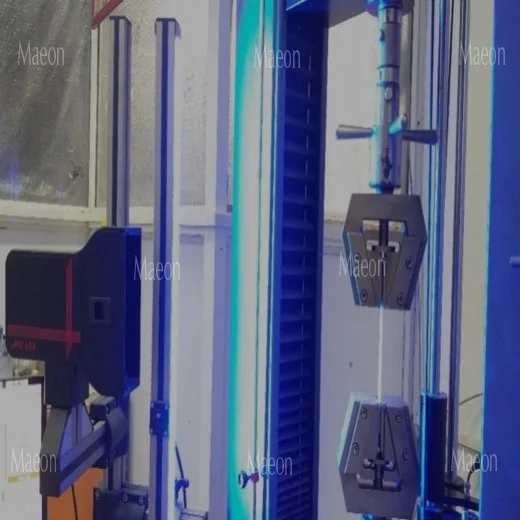

Tensile Strength & Elongation |

|

| |

Adhesion |

|

| |

Twist |

|

| |

Warp |

|

| |

Rise |

|

| |

Kink Test |

|

| |

Volumetirc Expansion |

|

| |

OD Expansion |

|

| |

Tension Test |

|

| |

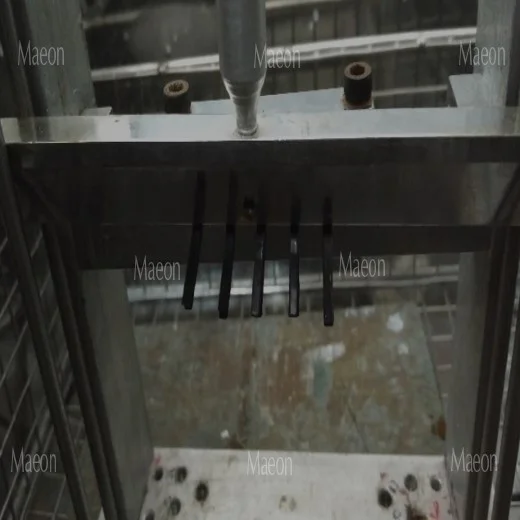

Permeability test |

|

| |

Fuel Permeation |

|

| |

Permiability to gas |

|

| |

Electrical Conductivity |

|

| |

Electromechanical degradation |

|

| |

Electrochemical degradation |

|

| |

Hydrostatic Pressure Test / Leakage |

|

| |

Elongation & Contraction |

|

| |

Proof Pressure |

|

| |

Hold Test |

|

| |

Bursting Test |

|

| |

Vacuum Test |

|

Thermal Propeties – Hot and Cold

| |

Low Temperature Test on hose |

|

| |

Low Temperature Test on tube & Cover |

|

| |

Strength Deterioration |

|

| |

Air Aging Test |

|

| |

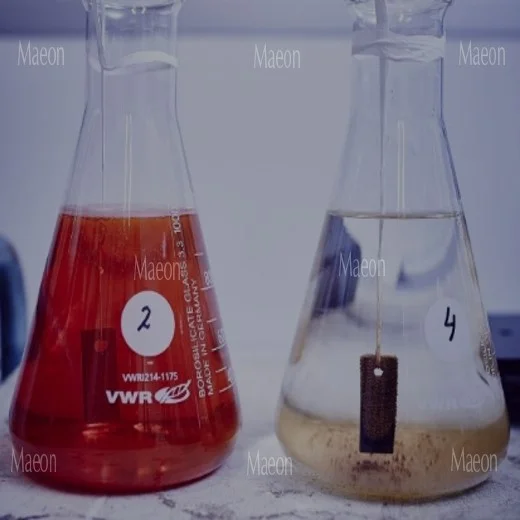

Immersion / Oil Resistance |

|

| |

Chlorine and detergent test |

|

| |

Odor and Taste test |

|

| |

Water absorption |

|

| |

Fungus Test |

|

| |

Resistance to Zinc Chloride |

|

| |

Methanol Fuel Resistance |

|

| |

Auto Oxidised Gasoline |

|

| |

Ozone test |

|

| |

Resistance to steam |

|

| |

Exposure to Xenon / UV |

|

PRODUCT SPECIFICATION TEST

Maeon Laboratories offer testing services for product approval / validation to national and international standards for Hoses and polymeric tubings. Some of types of hose testing, rubber hose testing, plastic hose testing, rubber tubes testing, plastic tube testing include products for water, air, fuel hoses, hy pressure hydraulic hoses, pneumatic hoses and agricultural hoses.

| HP1PR-1 |

Rubber Water Hose |

IS 444 : 1987 PCD 13 |

| HP1PR-2 |

Rubber Air Hose |

IS 446 : 1987 |

| HP1PR-3 |

Rubber Hose For Welding |

IS 447 : 1988 PCD 13 |

| HP1PR-4 |

Rubber Hose For Fuel Dispensing |

IS 2396 : 1988 PCD 13 |

| HP1PR-5 |

Water suction and discharge hose

of rubber, heavy duty covers |

IS 2410:1963 |

| HP1PR-6 |

RUBBER HOSE FOR SAND BLASTING |

IS 5894 : 1980 PCD 13 |

| HP1PR-7 |

RUBBER HOSE FOR LIQUEFIED

PETROLEUM GAS (LPG) |

IS 9573 : 1998 PCD 13 |

| HP1PR-8 |

High pressure hydraulic hose

for Underground mining |

BSC-174-1992 |

| HP1PR-9 |

Flexible Rubber Tubing For

Liquefied Petroleum |

IS 10908 : 1991 PCD 13 |

| HP1PR-10 |

Thermoplastic hoses (textile reinforced)

for water genral purpose |

IS 12585 : 1988 PCD 13 |

| HP1PR-11 |

Rubber hoses and hose assemblies.

Rubber-covered spiral wire

reinforced hydraulic type. |

EN 856 - 1996 |

| HP1PR-12 |

HIGH PRESSURE FIRE FIGHTING HOSE |

IS 14933 : 2001 CED 22 |

| HP1PR-13 |

Electrically Bonded Road and Rail

Tanker Hose of Rubber, Resistant to

Petroleum Products |

IS-10733 - 1983 |

| HP1PR-14 |

Rubber hose for LPG |

IS 9573:2012 |

| HP1PR-15 |

Wire reinforced rubber covered hydraulic hose |

IS 7651:1997 |

| HP1PR-16 |

Non-percolatng flexible fire fighting delivery hose |

IS 636 |

| HP1PR-17 |

Wire-braid-reinforced hydraulic types for oil-based or water-based fluids, Rubber hoses and hose assemblies — Specification |

ISO 1436 : 2017 |

| HP1PR-19 |

Anaesthetic and respiratory equipment — Low-pressure hose assemblies for use with medical gases |

ISO 5359 :2014 |

| HP1PR-20 |

Rubber hoses and hose assemblies — Textile-reinforced hydraulic types for oil-based or water-based fluids — Specification |

ISO 4079 |

| HP1PR-21 |

Rubber hoses for sand and grit blasting — Specification |

ISO 3861:1995 |

| HP1PR-22 |

Wire-braid-reinforced compact types for hydraulic applications |

ISO 11237-1 |

| HP1PR-23 |

Fire resistant fuel hose |

ISO 7840 |

| HP1PR-24 |

Nonmetallic fuel sytem tubing with one or more layers |

SAE J 2260 : 2004 |

| HP1PR-25 |

Rubber Hoses for Agricultural Spraying |

IS 1677:2018 |

| HP1PR-26 |

Polyurethane tubing for use primarily in pneumatic installations |

ISO/TS 11619:2014 |

| HP1PR-27 |

Rubber hoses and hose assemblies — Wire- or textile-reinforced single-pressure types for hydraulic applications — Specification |

ISO 18752: 2014 |

| HP1PR-28 |

Rubber hoses and hose assemblies — Textile-reinforced hydraulic types for oil-based or water-based fluids — Specification |

ISO 4079:2015 |

| HP1PR-29 |

Rubber heater and fuel hoses |

SAE 20R1 |

Pipes - Product & Material Testing

Testings differ for pipes depending on their end use. All critical tests for various types of polymeric pipes, of materials such as HDPE, PP, PVC, UPVC, CPVC etc. are conducted to customer specifications and to National and international standards. A brief of the tests and standards followed by Maeon Laboratories, potable water, hot and cold, high pressure water/ liquid lines, gaseous fuels, underground drainage, are listed above

| ASTM D2886 |

|

|

| ISO 1452-2 |

|

|

| IS 12235, IS 14885, IS 4984, IS 4985, IS 15328, IS 12786, IS 12701, IS 15778 |

|

|

Tensile and compression tests

| HP1ME-40 |

Tensile & Elongation properperties |

|

| HP1FN |

Compression test for pipes |

ASTM D2412 |

| HP1FN-17 |

Flattening Test |

|

| HP1FN-24 |

Burst Pressure |

|

| HP1FN-11 |

Resistance to Internal Hydrostatic Pressure at Constant internal Water Pressure |

|

| HP1FN-15 |

Resistance to external blows (impact resistance) at o'c |

|

| HP1FN-18 |

Internal Pressure Creep Rupture Test |

|

| |

Creep test, Tensile creep, Flexural creep test |

ISO 899-2 |

Environmental property test

| HP1EN-4 |

Effect on the composition of water |

|

| HP1EN-5 |

Resistance to sulfuric acid |

|

Weatherability property test

| HP1WE-2 |

Effect of sunlight |

|

| PE1WE-4 |

Resistance to weathering |

|

| HP1FN-19 |

Longitudinal reversion test |

|

| HP1FN-20 |

Axial Shrinkage |

|

| HP1MT-15 |

Organotin as tin aqueous solution |

|

| HP1MT-16 |

Resistance to dichloromethane at specified temperature |

|

| HP1MT-17 |

Titanium dioxide content |

|

| HP1MT-20 |

Overall migration |

|

| HP1MT-21 |

Density |

|

| HP1MT-25 |

Pigment dispersion |

|

| HP1MT-18 |

Vinyl Chloride monomer content |

|

| HP1MT-19 |

Ash and Sulphated ash |

|

| HP1ME-42 |

Adhesion |

|

| HP1MT-22 |

Carbon Black Dispersion and content |

|

| HP1MT-24 |

Volatile Matter Content |

|

| HP1MT-23 |

Oxidation Induction Time |

|

| HP1OP-2 |

Opacity |

|

| HP1TH-7 |

Vicat Softening Temperature |

|

| HP1TH-8 |

High Temperature Test |

|

| HP1TH-9 |

Melt Flow Rate |

|

| Joint /Sealing ring tightness |

|

|

| HP1FN-12 |

Leak-tightness of Elastomeric Sealing Ring T- Angular Deflection“ |

|

| HP1WE-3 |

Water tightness of joint |

|

| HP1FN-16 |

Ring Stiffness |

|

PRODUCT SPECIFICATION TEST

Quality of Rigid and Flexible Pipes are essential for their long term trouble free performance. Maeon Laboratories offers testing PVC pipe testing services for product approval/validation to national and international standards for pipes and pipe fittings. Some of standards covering different types of Pipes for which Maeon has facility to test are listed above.

| HP1PR-30 |

PVC pipesfor potable Water |

IS 4985 |

| HP1PR-31 |

HDPE pipes for potable water |

IS 4984 |

| HP1PR-32 |

Unplasticized Polyvinyl Chloride (UPVC) Single Wall Corrugated Pipes for Drainage |

IS 9271 |

| HP1PR-33 |

Irrigation Equipment--Polyethylene Pipes for Irrigation |

IS 12786 |

| HP1PR-34 |

PVC PIPE - POTABLE HOT AND COLD WATER |

IS 15778 |

| HP1PR-35 |

Thermoplastics Pipes and fittings |

IS 12235-1 |

| HP1PR-36 |

POLYETHYLENE PIPES FOR THE SUPPLY OF GASEOUS FUELS |

IS 14885 : 2001 CED 50 |

| HP1PR-37 |

Non-pressure Pvc -U -Underground drainage and sewerage systems |

IS 15328 : 2003 |

| HP1PR-38 |

CHLORINATED PVC PIPES FOR POTABLE HOT AND COLD WATER DISTRIBUTION SUPPLIERS |

IS 15778 : 2007 CED 1 |

| HP1PR-39 |

POLYPROPYLENE-RANDOM COPOLYMER PIPES FOR HOT AND COLD WATER SUPPLIES |

IS 15801 : 2008 CED 50 |

MAEON Laboratories are pioneers in conducting Hose testing, Tube testing, Pipe testing for various industrial, agricultural, water and fuel transfer, domestic product applications The range of tests required for hose and pipe testing include those carried out directly on the product and tests made on the materials used for the Hose/Pipe products.

MAEON Laboratories are pioneers in conducting Hose testing, Tube testing, Pipe testing for various industrial, agricultural, water and fuel transfer, domestic product applications The range of tests required for hose and pipe testing include those carried out directly on the product and tests made on the materials used for the Hose/Pipe products. We specialize in product testing laboratory, where products are evaluated and ensured to meet your quality, safety, and regulatory standards. Our laboratories have advanced equipment and experts who conduct tests to analyze performance, durability, chemical composition, and reliability. The results of these tests help your business to improve products, enhance customer satisfaction, and comply with industry regulations. Product testing laboratories play a vital role in ensuring high-quality products and protecting consumers.

We specialize in product testing laboratory, where products are evaluated and ensured to meet your quality, safety, and regulatory standards. Our laboratories have advanced equipment and experts who conduct tests to analyze performance, durability, chemical composition, and reliability. The results of these tests help your business to improve products, enhance customer satisfaction, and comply with industry regulations. Product testing laboratories play a vital role in ensuring high-quality products and protecting consumers. Tube testing laboratory is gradually being phased out of normal hospital pretransfusion testing in favor of gel and solid-phase testing, as it is deemed less sensitive than more current methods.

Tube testing laboratory is gradually being phased out of normal hospital pretransfusion testing in favor of gel and solid-phase testing, as it is deemed less sensitive than more current methods. Plastic pipe testing is required throughout the manufacturing process of various pipes as as PVC, HDPE, and others. During the production process, this testing is necessary to determine the objects' strength, quality, and resistance.There are a variety of tests that must be performed on PVC pipe testing, and we offer a variety of equipments that can produce accurate findings.

Plastic pipe testing is required throughout the manufacturing process of various pipes as as PVC, HDPE, and others. During the production process, this testing is necessary to determine the objects' strength, quality, and resistance.There are a variety of tests that must be performed on PVC pipe testing, and we offer a variety of equipments that can produce accurate findings. HDPE pipe testing is a flexible plastic pipe that is used to transport fluids and gases. It is frequently utilised to replace ageing concrete or steel mains pipes. Its high level of impermeability and strong molecular bond make it suited for high pressure pipelines, and it is made from the thermoplastic HDPE.

HDPE pipe testing is a flexible plastic pipe that is used to transport fluids and gases. It is frequently utilised to replace ageing concrete or steel mains pipes. Its high level of impermeability and strong molecular bond make it suited for high pressure pipelines, and it is made from the thermoplastic HDPE.