Expertised in Plastic testing laboratory for a wide range test parameters for your Plastics Materials and Plastic Products in Maeon laboratory. Polymer material testing analysis, Polymer Mechanical properties, Polymer Chemical Properties, Polymer electrical properties

conducted covered many international standards.

Expertised in Plastic testing laboratory for a wide range test parameters for your Plastics Materials and Plastic Products in Maeon laboratory. Polymer material testing analysis, Polymer Mechanical properties, Polymer Chemical Properties, Polymer electrical properties

conducted covered many international standards.

We provide you with cutting-edge polymer material testing technology as well as unequaled experience and highly qualified personnel. Our polymer material testing ensures that your polymeric materials are safe and efficient to use, as well as in compliance with all applicable national and international standard

We provide you with cutting-edge polymer material testing technology as well as unequaled experience and highly qualified personnel. Our polymer material testing ensures that your polymeric materials are safe and efficient to use, as well as in compliance with all applicable national and international standard

Plastic testing lab usually respond to the forces they are subjected to, being deformed to a greater or lesser extent, and possibly ending up in breakage.

Plastic testing lab usually respond to the forces they are subjected to, being deformed to a greater or lesser extent, and possibly ending up in breakage.

Plastic Material Testing Lab plays a critical role in the life cycle of a polymer, from the raw material to the compound through to the semi-finished and finished product. Each stage has different test requirements, and each end user may require a different test solution depending on their role, whether it is in Product Development (R&D), Quality Control (QC), Testing Services (TS), or Research (R).

Plastic Material Testing Lab plays a critical role in the life cycle of a polymer, from the raw material to the compound through to the semi-finished and finished product. Each stage has different test requirements, and each end user may require a different test solution depending on their role, whether it is in Product Development (R&D), Quality Control (QC), Testing Services (TS), or Research (R).

Polymer material testing and plastic testing lab are among the most versatile materials on the planet, and they are employed in virtually every area of our life. They've changed the way consumer goods and industrial applications like aerospace, automotive, electronics, and packaging are made. Our scientists have the industry expertise to provide you with the information you need to advance product development, assure compliance, and launch a successful market launch for the application you're working on.

Polymer material testing and plastic testing lab are among the most versatile materials on the planet, and they are employed in virtually every area of our life. They've changed the way consumer goods and industrial applications like aerospace, automotive, electronics, and packaging are made. Our scientists have the industry expertise to provide you with the information you need to advance product development, assure compliance, and launch a successful market launch for the application you're working on.

Plastics test equipment and accessories that meet ISO, ASTM, and JIS plastics testing Plasticsplastic material testing test equipment and accessories that meet ISO, ASTM, and JIS plastics testing standards are provided from us. are provided from us.

Plastics test equipment and accessories that meet ISO, ASTM, and JIS plastics testing Plasticsplastic material testing test equipment and accessories that meet ISO, ASTM, and JIS plastics testing standards are provided from us. are provided from us.

We can assess how your products and servicesplastic material testing meet and exceed quality, safety, sustainability, and criteria by bringing quality toplastic material testing life. We help you recognise and minimize inherent hazards in your polymer and plastics operations, supply chains, and business processes.

We can assess how your products and servicesplastic material testing meet and exceed quality, safety, sustainability, and criteria by bringing quality toplastic material testing life. We help you recognise and minimize inherent hazards in your polymer and plastics operations, supply chains, and business processes.

Hardness Property Test

Determination of hardness can be done for substances classified as vulcanized (thermoset) rubber, thermoplastic elastomers, cellular materials, elastomeric materials, gel-like materials, and plastics. Durometer scale is a type of measurement for rubber and plastic material hardness. Generally flexible plastic materials fall under the Scale Shore A. Hard plastics use Shore D. Hardness of other materials such as Foams and soft sponges can be checked using scales Shore OO and by scale Asker C

Determination of this Ball indentation hardness is generally used for harder plastics, It measures the resistance of plastics towards indentation and provides necessary hardness values. Generally Type R,M indenter is used for Plastics hardness measurements.

| PL1ME-1 |

Hardness (Durometer) |

ASTM D2240, JIS K7215, ISO 868, IS 13360 P5 |

| PL1ME-2 |

Rockwell Hardness |

ASTM D785, JIS K7202, IS 13360 P5, ISO 2039 |

Stress Strain Property Test

Tensile properties of Plastics provide very useful information for its engineering design purpose. Characteristics such as Tensile strength, Elongation, Elongation at Yield, Modulus of elasticity and other tensile properties can be determined.

| PL1ME-3 |

Tensile strength |

ASTM D638, ISO 527, JIS K7161, IS 13360 |

| PL1ME-3 |

Elongation@Break |

ASTM D638, ISO 527, JIS K7161, IS 13360 |

| PL1ME-7 |

Compressive Strength |

ISO 604 |

| PL1ME-3 |

Young’s Modulus |

|

Impact Property Test

Plastics show significantly different Absorption energy when subjected to an impact load. A measure of impact resistance of material is useful for Quality estimation purposes.

The Charpy Impact test indicates the energy of break standard test specimen under Standard conditions with notching.

| PL1ME-5 |

Izod Impact Strength |

ASTM D256, ISO 180, JIS K7110, IS 13360 P5 |

| PL1ME-6 |

Charpy Impact Strength |

ASTM D6110, ISO 179, IS 13360 P5, JIS K7111 |

Flexural Property Test

Determination of Flexural properties are important for specifying grades and the control of quality. Flexural Strength, Modulus, Flexural strain. A rectangular test specimen is placed on 2 supports and loaded at the centre of supports

| PL1ME-4 |

Flexural strength |

ASTM D790, ISO 178, JIS K7171, IS 13360 P5 |

| PL1ME-4 |

Flexural Modulus |

ASTM D790, ISO 178, JIS K7171, IS 13360 P5 |

Material Property Test

This test is of prime importance for the Identification of material. It is also used to indicate us the physical changes if any, loss of plasticizers, absorption of solvent or because of any other cause.

Melting point is determined for rubber processing chemicals for verifying quality of material. Melting point values which are deviating from known standard substance indicate poor quality.

| PL1MT-1 |

Density and Specific Gravity |

ASTM D 792, ISO 1183, IS 13360 P3, JIS K7112 |

| PL2MT-7 |

Melting point by Capillary Tube |

ISO 3146, IS 13360 P6 |

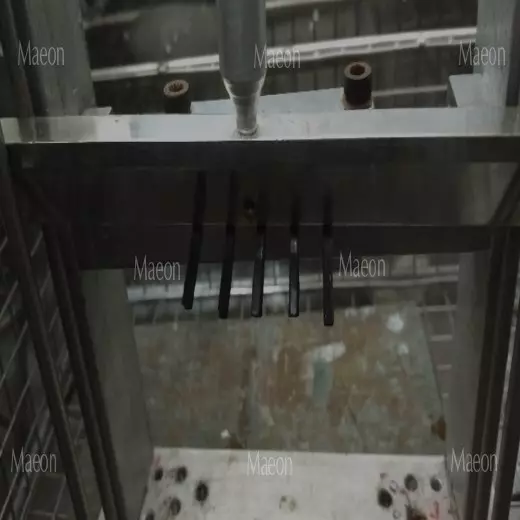

Weathering Behaviour Test

A weathering test is a system for determining weathering characteristics of materials and coatings. Such tests are used to predict durability or to monitor changes in mechanical properties during weathering of materials.

MAEON Laboratory has facility for accelerated weathering - The process of weathering is accelerated through the use of specially designed weathering chambers. Gas-discharge lamps (e.g. xenon arc lamps) or fluorescent lamps are used to simulate/accelerate the effects of sunlight.

Both methods are based on regular monitoring of characteristics reflecting an aging process like:Mechanical properties, Elongation at break, Tensile properties, Impact strength also the Visible characteristics Crack formation, Chalking, Changes in colour or gloss.

| PL1WE-1 |

Weathering Resistance by Xenon and Fluorescent UV |

ASTM G154, ASTM G155, ISO 4892 |

| PL1BI-1 |

Biodegradability |

|

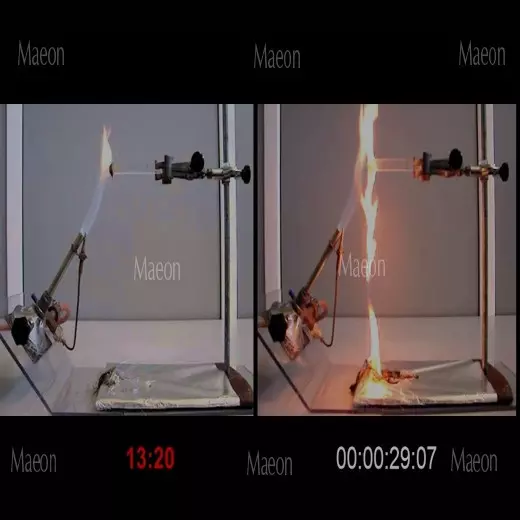

Flammability Properties Test

Rate of burning of plastics, and also rate and extent of burning characterizes are studied for understanding processing character and deterioration

| PL1FL-1 |

Rate of Burning |

ASTM D635, UL94, ISO 3795, IS 15061, FMVSS 302, MS 300-08 |

| PL1FL-1 |

Extent & Time of Burning |

ASTM D635, UL94, ISO 3795, IS 15061, FMVSS 302, MS 300-08 |

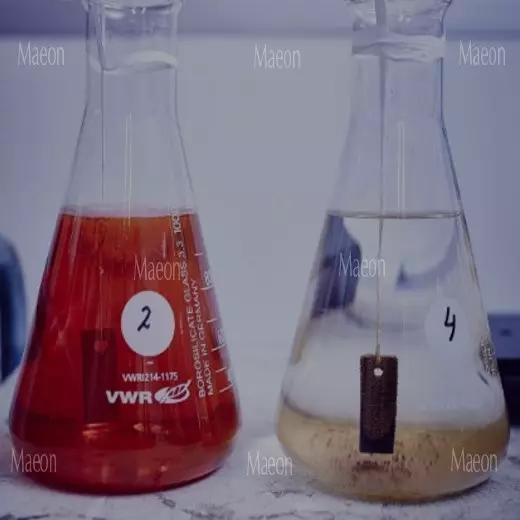

Chemical Analysis Test

Quantification of carbon black contained in Olefinic plastics can be performed at MAEON laboratories. This test is useful for investigative, reconstructions and quality control purposes

Karl Fisher Titration is a technique for the determination of moisture content. The technique was developed by a chemist named Karl Fischer. It is based on a reagent which reacts with water and converts the water into a non-conductive chemical.

| PL1MT-9 |

Moisture content by Karl Fischer |

|

| PL1MT-8 |

Filler Content |

|

| PL1MT-2 |

Carbon Black Content in Olefin Plastics |

ASTM D1603 |

Thermal Property Test

Maeon laboratories has facility for evaluating plastics for its behaviour at low temperature. A test device determines the brittleness point of plastics are under impact at low temperature.

| PL1TE-3 |

Low Temperature Brittleness Properties |

ASTM D746, ISO 974, IS 13360 P6 |

| |

High temperature Properties |

|

Temperature Property Test

Fogging tests measure the tendency for plastic or elastomeric materials to volatize substances which can condense and collect on other surfaces when in use. These tests provide 2 methods for evaluating the likelihood of a material to leave a light scattering film on a glass surface (photometric method), or to deposit foreign material onto an aluminum foil surface (gravimetric method). The tests are used to evaluate materials to be used in automotive or other vehicle interiors.

| PL1TE-4 |

Fogging Resistance |

|

Chemical Property Test

Evaluation of Plastic products functioning under chemical contact for mechanical property changes is important. Extend of deterioration in properties can be estimated after immersion in the specified chemicals.

| PL1TE-1 |

Resistance of Plastics to Chemical Reagents |

ASTM D543, ISO 175 |

| PL1TE-2 |

Water Absorption of Plastics |

ASTM D570, ISO 62, IS 13360 P8, JIS K7209 |

Melting Property Test

MFI is largely influenced by the material’s physical properties, molecular structure and the rheological character. The test helps to determine the uniformity of the flow rate of polymer at a particular condition.

| PL1TH-1 |

Melt Flow Rate |

ASTM D 1238, ISO 1133, JIS K7210, IS 13360 P4 |

| PL1TH-1 |

Melt Flow Index |

ASTM D 1238, ISO 1133, JIS K7210, IS 13360 P4 |

Deflection Property Test

A measure of the Vicat softening temperature of plastics is useful for the characterization of plastics by its heat-softening qualities.-The test determines the temperature at which a standard indenter (needle) penetrates 1mm into the surface of a test specimen under load.

The test method covers a procedure to determine the temperature at which plastics deform when it is subjected high temperature and load.

| PL1TH-2 |

Vicat Softening temperature of plastics |

ASTM D1525, ISO 306, IS 13360 P6, JIS K7206 |

| PL1TH-3 |

Deflection Temperature of Plastic |

ASTM D648, IS 13360 P6, ISO 75, JIS K7191 |

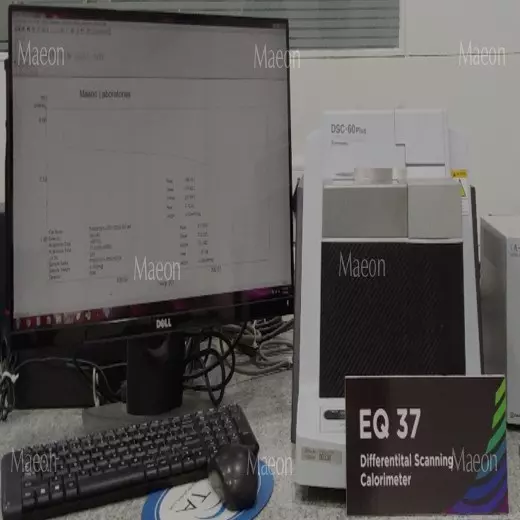

Analytical Test

The polymers in a given material or product can be determined by Infrared spectrophotometry. The infrared spectrum of the test specimen is superimposed on a reference spectrum and compared for determination of polymer used

We offer testing of plastics for the determination of Transition temperatures, such as Enthalpies of Fusion and Crystallization of Polymers – including Tm, Tg, Tc. Other measurements from DSC include Thermal stability, Decomposition temperature, Oxidative Induction Times etc.,

The composition of compound of rubber / plastics such as Low boiling fractions, polymer, carbon and fillers are quantitatively determined by TGA – Thermogravimetry. A small mass of test sample is subjected to controlled heating under specific environment and the mass loss over a temperature range is measured.

| PL1MT-3 |

FTIR |

ASTM D3677, ASTM E1252 |

| PL1MT-5 |

TGA |

ASTM E1131, ISO 11358, JIS K7120 |

| PL1MT-6 |

DSC |

ASTM D3418, ISO 11357, ASTM D3895 |

Optical Test

Consumer and Automotive products require the appearance to be uniform and its best. This requires control of colour, gloss, haze, transparency using Spectrophotometers, gloss meter, haze meter etc… MAEON has facility for all such requirements

| PL1OP-1 |

Color and Yellowness Index Measurements |

|

| PL1OP-2 |

Haze and Transmission Properties |

|

Electrical Tests

Many of the applications of plastic materials involve measurement of electrical properties of Composites, some have been listed below:

| CP1EL-1 |

Volume Resistivity and Surface Resistivity of composites |

ASTM D257 |

| CP1EL-2 |

Dielectric Constant and Dissipation Factor of composites |

ASTM D150 |

| CP1EL-3 |

Dielectric Strength of composites |

ASTM D149 |

A plastic testing laboratory in Chennai, Maeon laboratories assists in testing, plastic testing standardsprocess optimization, formulation, chemical analysis, and more.

Along with plastic testing, polymer material testing Maeon Lab is expertise in rubber testing laboratory in Chennai.

Our laboratory follows quality standards to polymer material testing secure the best possible test resultspolymer material testing and services.

polymer materialplastic testing standards testing

Expertised in Plastic testing laboratory for a wide range test parameters for your Plastics Materials and Plastic Products in Maeon laboratory. Polymer material testing analysis, Polymer Mechanical properties, Polymer Chemical Properties, Polymer electrical properties

conducted covered many international standards.

Expertised in Plastic testing laboratory for a wide range test parameters for your Plastics Materials and Plastic Products in Maeon laboratory. Polymer material testing analysis, Polymer Mechanical properties, Polymer Chemical Properties, Polymer electrical properties

conducted covered many international standards. We provide you with cutting-edge polymer material testing technology as well as unequaled experience and highly qualified personnel. Our polymer material testing ensures that your polymeric materials are safe and efficient to use, as well as in compliance with all applicable national and international standard

We provide you with cutting-edge polymer material testing technology as well as unequaled experience and highly qualified personnel. Our polymer material testing ensures that your polymeric materials are safe and efficient to use, as well as in compliance with all applicable national and international standard Plastic testing lab usually respond to the forces they are subjected to, being deformed to a greater or lesser extent, and possibly ending up in breakage.

Plastic testing lab usually respond to the forces they are subjected to, being deformed to a greater or lesser extent, and possibly ending up in breakage. Plastic Material Testing Lab plays a critical role in the life cycle of a polymer, from the raw material to the compound through to the semi-finished and finished product. Each stage has different test requirements, and each end user may require a different test solution depending on their role, whether it is in Product Development (R&D), Quality Control (QC), Testing Services (TS), or Research (R).

Plastic Material Testing Lab plays a critical role in the life cycle of a polymer, from the raw material to the compound through to the semi-finished and finished product. Each stage has different test requirements, and each end user may require a different test solution depending on their role, whether it is in Product Development (R&D), Quality Control (QC), Testing Services (TS), or Research (R). Polymer material testing and plastic testing lab are among the most versatile materials on the planet, and they are employed in virtually every area of our life. They've changed the way consumer goods and industrial applications like aerospace, automotive, electronics, and packaging are made. Our scientists have the industry expertise to provide you with the information you need to advance product development, assure compliance, and launch a successful market launch for the application you're working on.

Polymer material testing and plastic testing lab are among the most versatile materials on the planet, and they are employed in virtually every area of our life. They've changed the way consumer goods and industrial applications like aerospace, automotive, electronics, and packaging are made. Our scientists have the industry expertise to provide you with the information you need to advance product development, assure compliance, and launch a successful market launch for the application you're working on. Plastics test equipment and accessories that meet ISO, ASTM, and JIS plastics testing Plasticsplastic material testing test equipment and accessories that meet ISO, ASTM, and JIS plastics testing standards are provided from us. are provided from us.

Plastics test equipment and accessories that meet ISO, ASTM, and JIS plastics testing Plasticsplastic material testing test equipment and accessories that meet ISO, ASTM, and JIS plastics testing standards are provided from us. are provided from us. We can assess how your products and servicesplastic material testing meet and exceed quality, safety, sustainability, and criteria by bringing quality toplastic material testing life. We help you recognise and minimize inherent hazards in your polymer and plastics operations, supply chains, and business processes.

We can assess how your products and servicesplastic material testing meet and exceed quality, safety, sustainability, and criteria by bringing quality toplastic material testing life. We help you recognise and minimize inherent hazards in your polymer and plastics operations, supply chains, and business processes.