Product testing is a quality, dependability, and durability extremely important part of the development process. Quality means determining whether or not your product will perform as expected. Every product needs to test in a product testing laboratory to ensure that they meet quality standards.

Product testing is a quality, dependability, and durability extremely important part of the development process. Quality means determining whether or not your product will perform as expected. Every product needs to test in a product testing laboratory to ensure that they meet quality standards.

Product durability testing aids in the improvement of your product and the generation of more income through client retention and happiness. Quality assurance and ensuring that all standards are met and rules are followed before distribution are two of the most critical parts of product testing.

Product durability testing aids in the improvement of your product and the generation of more income through client retention and happiness. Quality assurance and ensuring that all standards are met and rules are followed before distribution are two of the most critical parts of product testing.

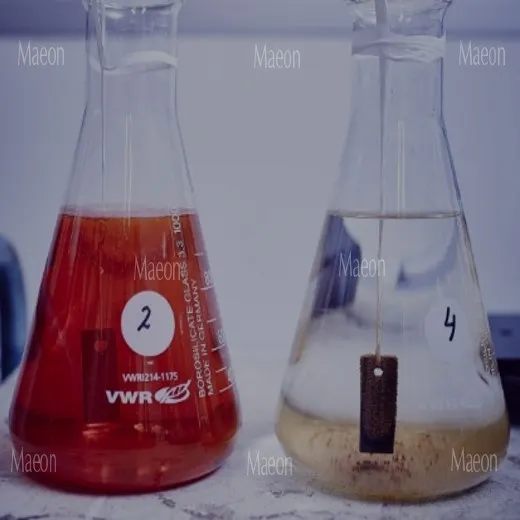

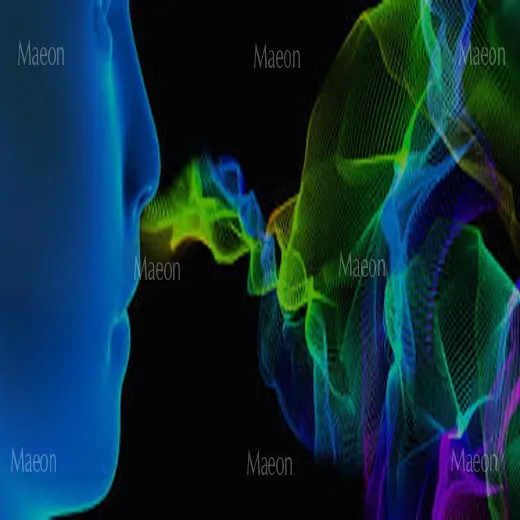

The effect of fogging is created when gases of various volatile organic compounds, which can evaporate from trim materials in vehicle interiors, are condensed. Maeon Laboratory fogging testing lab in Chennai conducts tests such as DIN 75201, DIN 75201, ISO 6452, SAE J1756, and PV 3015.

The effect of fogging is created when gases of various volatile organic compounds, which can evaporate from trim materials in vehicle interiors, are condensed. Maeon Laboratory fogging testing lab in Chennai conducts tests such as DIN 75201, DIN 75201, ISO 6452, SAE J1756, and PV 3015.

Fogging is a common phenomenon that occurs in various products, such as car interiors, mirrors, eyeglasses, and other plastic products. To ensure product safety and quality, fogging testing labs perform a range of tests to measure the extent of fogging in products. These tests determine the number of volatile materials that evaporate from the product and whether they deposit onto surfaces in the form of fog.These tests are frequently specified by many OEM standards and International Standards and being carried out in the facilities of Maeon Laboratories. Some are detailed in the following listing for ready reference.

Fogging is a common phenomenon that occurs in various products, such as car interiors, mirrors, eyeglasses, and other plastic products. To ensure product safety and quality, fogging testing labs perform a range of tests to measure the extent of fogging in products. These tests determine the number of volatile materials that evaporate from the product and whether they deposit onto surfaces in the form of fog.These tests are frequently specified by many OEM standards and International Standards and being carried out in the facilities of Maeon Laboratories. Some are detailed in the following listing for ready reference.

Product functional Testing that verifies that the product system meets the functional requirements. These forms of functional tests assist organizations in ensuring that digital goods meet requirements at all levels, from the code to the system as a whole.

Product functional Testing that verifies that the product system meets the functional requirements. These forms of functional tests assist organizations in ensuring that digital goods meet requirements at all levels, from the code to the system as a whole.

FN1FN-1 |

Heat Cycle Resistance / Heat and Humidity cycle Resistance |

MS 210-05 Cl 4.3.1 MS 210-12 CL 4.2, MS 210-06 Cl 4.3 ES 91100-07 Cl 6.3, MS 200-46 Cl 4.1 ES-W60042 Cl 4.3 |

|---|---|---|

| FN1FN-3 | Heat Ageing Resistance | MS 210-05 Cl 4.4 MS 200-46 Cl 4.6, MS 200-46 Cl 4.8 |

| FN1FN-2 | Thermal Shock Resistance | MS 210-05 Cl 4.3.2 |

|---|

| FN1FN-22 | Xenon Weatherability test | ISO 105-B02 JIS L0843 ASTM D6695 ASTM D7869-13 ,SAE J1885 SAE J2412 PV 1303 PV 3930 SAE J1960 SAE J2413 SAE J2527 ASTM G151 ASTM G155 ASTM D4303 ASTM D4355 ISO 105-B04 ISO 105-B06 ISO 11341 ISO 3917 ISO 4892-1 ISO 4892-2 ISO 12040 |

|---|---|---|

| FN1FN-23 | UV Weatherability test | ISO 4892-3 ASTM D1148 ASTM D3424 ASTM D4101 ASTM D4329 ASTM D4587 ASTM D4674 ASTM D750 ASTM G151 ASTM G154 SAE J2020 |

| FN1FN-4 | Fading Resistance / Weatherability Test | MS 210-05 Cl 4.5 MS 210-12 CL 4.3 MS 210-06 Cl 4.4.2 ES-W60042 Cl 4.4.1 |

FN1FN-5 |

Chemical Resistance - Plastic parts |

MS 210-05 Cl 4.7 MS 210-12 CL 4.6 MS 210-06 Cl 4.7 ES-W60042 Cl 4.7 |

|---|

| FN1FN-6 | Wear Resistance | MS 210-05 Cl 4.8 |

|---|---|---|

| FN1FN-7 | Scratch Resistance: Erichsen Method | MS 210-05 Cl 4.9.1 MS 210-06 Cl 4.9 |

| FN1FN-8 | Scratch Resistance: Sapphire Method | MS 210-05 Cl 4.9.2 |

| FN1FN-24 | Pencil hardness test | ASTM D3363 ISO 15184 JIS K5400 JIS K5600 |

|---|---|---|

| FN1FN-14 | Scuffing test – rubbing | MS 210-05 Cl 4.15 |

FN1FN-9 |

Impact Resistance - Plastic parts |

MS 210-05 Cl 4.10.1 MS 210-12 CL 4.7 MS 210-06 Cl 4.8 ES-W60042 Cl 4.8 |

|---|

FN1FN-10,27 |

Fogging Resistance Test |

MS 210-05 Cl 4.11 MS 300-54 DIN 75201 DIN 75201 ISO 6452 SAE J1756 PV 3015 |

|---|

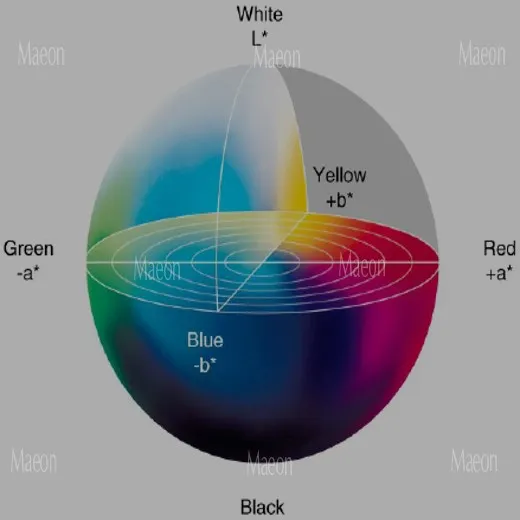

| FN1FN-25.28 | Colour determination, colour difference, transmittance measurements | ASTM D6290, ISO4582 ASTM E313 ASTM E1347-06 |

|---|

| FN1FN-21 | Haze and Transmittance measurements | ASTM D1003 ISO 14782 IS 2508 ASTM D2103 ISO 13468-1 ISO 13468-2 ASTM D1044 JIS K7105 JJIS K7361 JIS K7136 |

|---|

| FN1FN-29 | Yellowness Index | ISO 17223 ASTM D1925 |

|---|

| FN1FN-30 | Grey Scale – Colour change | ISO 105–A02 |

|---|---|---|

| FN1FN-31 | Grey scale - Staining | ISO 105-A03 |

FN1FN-15 |

Gloss Measurements |

MS 210-05 Cl 4.16 ASTM D2457, IS 13360 P9 S7 ISO 2813 IS 2508 |

|---|

| FN1FN-16, 18 | Water Spray, Water Jet tests | IEC 60529-IP64, IP65, IP66, IP69K, DIN 40050, MS 210-07, MS 210-12 CL 4.5 MS 210-06 Cl 4.6, ES-W60042 Cl 4.6 |

|---|

FN1FN-19 |

Odour Testing |

VDA 270 GMW 3205 ASTM E1870 |

|---|

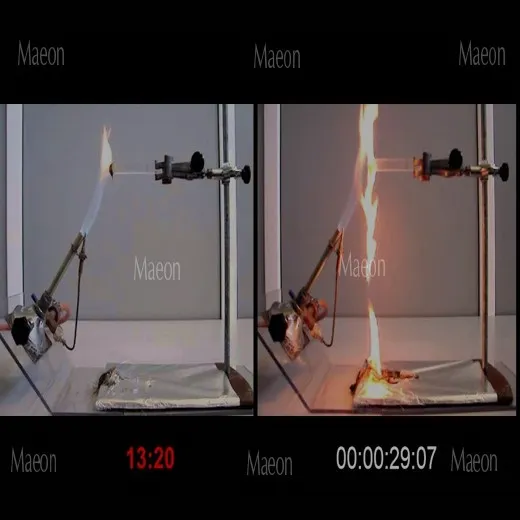

| FN1FN-20 | Flammability test | GMW 3232 |

|---|---|---|

| Vertical Burning tests | ||

| Horizontal Burning tests | ||

| Limiting Oxygen Index LOI |

| FN1FN-32, 33 | Fatique tests, Durability tests | ISO 13628-16 |

|---|

| FN1PR-3 | Standard Test Method – Exterior Plastic Parts | MS 200-48 : 1998: EN |

|---|---|---|

| FN1PR-4 | Mouled Plastic Parts - Interior Use | MS 210-05 : 2004 : EN |

| FN1PR-5 | Molded Plastic Parts – Exterior Use | MS 210-06 : 2007 :EN |

| FN1PR-1 | Synthetic Rubber compounds | MS 120-89 : 1978 : EN |

| FN1PR-2 | Test Standard – Soft Vulcanized Rubber | MS 200-41 : 2004 EN |

| FN1PR-6 | Polyamide 66 (Non-reinforced) | MS 211-46 : 2008 :EN |

| FN1PR-7 | Polyamide 66 (GF, MF – Reinforced) | MS 211-47 : 2006 : EN |

| FN1PR-8 | HCPP + LDPE Alloy | MS 213-26 : 2006 : EN |

| FN1PR-9 | Polypropylene filled with Talc | MS 213-28 : 2008 : EN |

| FN1PR-10 | Polypropylene Foam | MS 213-41 : 2000 : EN |

| FN1PR-11 | ABS – Heat Resistance | MS 225-18 : 1999 : EN |

| FN1PR-12 | Polyacetal (Acetal Copolymer, oxymethylene Copolymer) | MS 237-09 : 2007 : EN |

| FN1PR-13 | Sponge Rubber | MS 260-13 : 2005 : EN |

| FN1PR-14 | Flammability Resistance – Interior Materials | MS 300-08 : 2006 : EN |

| FN1PR-15 | Test Standard – tapes, film (with Pressure Sensitive Adhesives) | MS 300-33 : 1989 : EN |

| FN1PR-16 | Test Method Of Odor For Interior Materials | MS 300-34 : 2008 : EN |

| FN1PR-17 | Standard Test Method – Fogging | MS 300-54 : : 2002 : EN |

| FN1PR-19 | Stripe Tape – Interiors and Exteriors | MS 373-14 : 2003 : EN |

| FN1PR-20 | Testing Methods for Coatings and Coating Films | MS 600-35 : 1996 : EN |

| FN1PR-21 | Tape (Double – Side Adhesive) – Mark, Emblem | MS 711-10 : 2005 : EN |

| FN1PR-22 | Tubes - Interior | ES 91404-00, MS 213-36, MS 221-33 |

| FN1PR-23 | Harness Clip | ES 91600-00 |

| FN1PR-24 | Fuse Box | ES 91820-05, ES 91100-07 |